| This

is a 19 foot 1957 Bell Boy Cuddy cabin boat for full restoration back

to her glory.

Page

3 of many |

Home

|

|

|

|

This

makes the transom 2 and 3/4 inch thick. No flex, glass both sides of

each layer, all holes glass filled.

|

|

There

is always a void to fill on the edges no matter how good you get at

it.

This

was a mix of Epoxy Resin and glass fibers in a paste. Goes in well

with a putty knife. This goes in on each layer too.

|

|

Click

on any image to see larger image. |

|

|

|

Just

more of the fillit |

|

Its

time to put the knee in and build a damn to keep the foam from getting

into this area. The foam will be on both sides of this box.

|

| |

|

|

|

|

|

Just

another view of the knee and fillit. |

|

Next

is the floor. |

| |

|

|

|

|

|

After

fastening down the floor with all stainless fasteners, all the sides

and seams have been taped and glassed to keep any water from ever

getting under the floor.

|

|

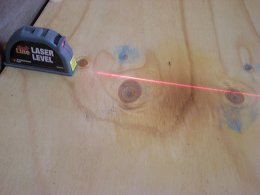

Little

trick before the floor goes down for the last time. I marked the frame

locations on the side of the hull as so I would know where the center

of the frames would be.

Laser

works great for this. |

| |

|

|

|

|

|

Here

is a picture, out of order showing the port side has been covered

with fiberglass matting for better strength and wear.

It

does show the cabin floor going up to the cabin bulkhead.

|

|

The

best way it to just flat fill all the holes and start fresh.

This

keeps the Epoxy slurry from running down the insides of the hull and

cabin top.

|

| |

|

|

|

|

|

All

the small holes can be filled with the Evercoat Lite Cat Hair mix.

(They really don;t use cat hair, its Fiberglass hairs ;-)

Larger

holes have to be ground and Fiberglass matting built up to make sure

it never stress cracks or opens up..

|

|

Here

is the 2 and 3/4 inch transom.

Hang

a big horse on this one if you like.

|

| |

|

|

|

|

Next

Page ----->

|